Bread Production

Scobie offers a comprehensive range of specialist bakery equipment to bread and roll producers.

From entire plants devoted to bread baking equipment, to individual machines including dough dividers, moulders and automatic bun dividers, we have the tools to meet your needs. Our current clients include major supermarkets and bulk bread producers. We also supply standalone bread-making equipment to many independent bakers. The quality bakery equipment all our clients achieve with Scobie Bakery is testament to our outstanding products and bakery expertise. From a specialist machine to a sophisticated production line, we can offer a fully automated, continuous system.

We can also supply parts and service for the full range of Glimek equipment.

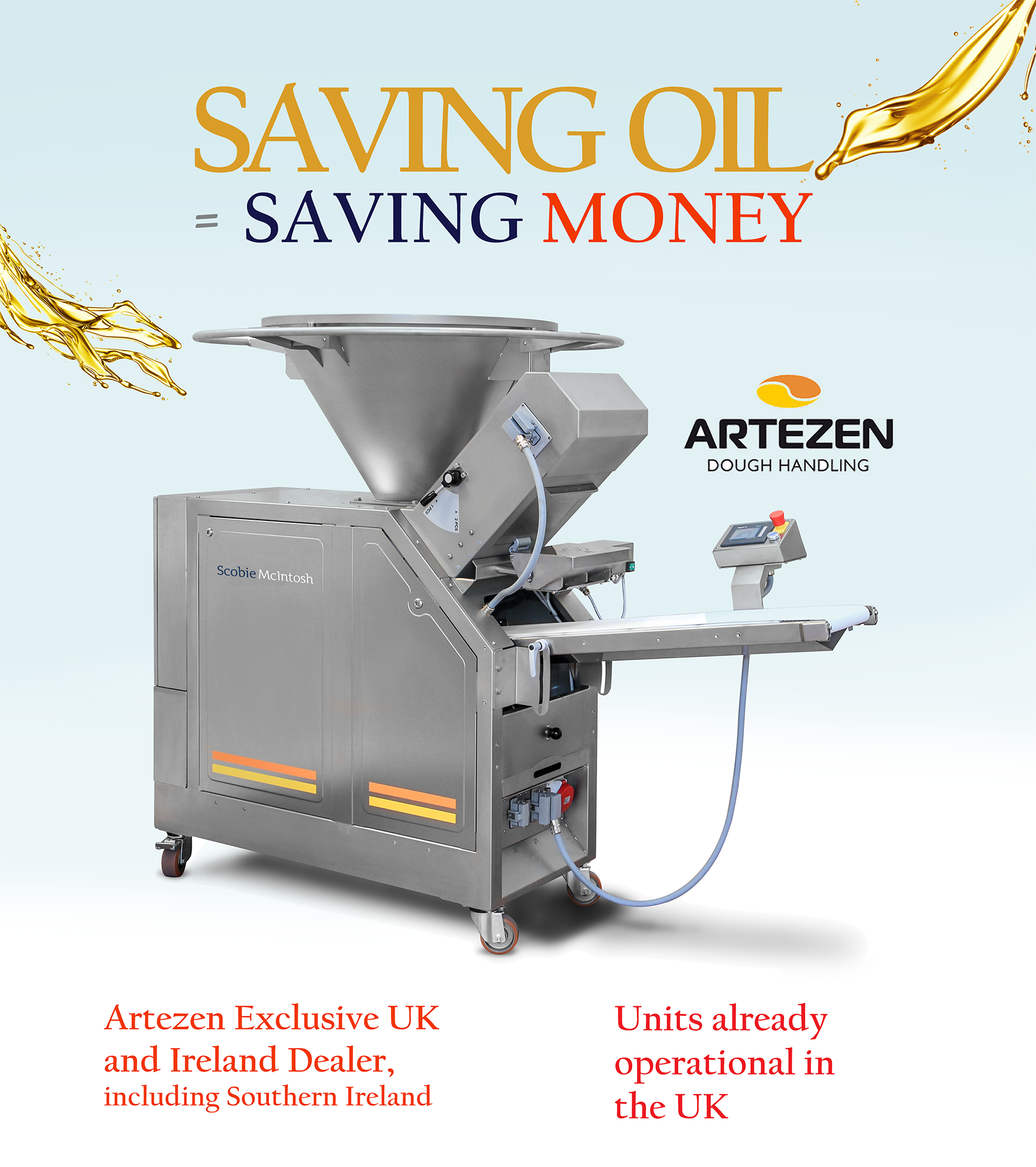

Make Money with Artezen

Example 1: Gluten free bread

Our client in the UK is one of Europe’s largest manufacturers of gluten free bread, delivering throughout five European countries. A clever strategy since gluten free bread is universal, the same kind is consumed in France, Germany or Italy.

When replacing two of his Dutch made industrial dividers, the baker looked for a clever solution. Calybra works oil free, saving him more than 6.000 euro per divider per year. The shape and quality of the product is now such that it can be loaded directly into the baking tins, saving another 13.000 euro a year in labor costs. His customers are reassured that their gluten free bread hasn’t been in contact with divider oil, his employees cheerful with less hours of cleaning the machine and their workplace.

Example 2: Industrial baking

A large bakery wanted to guarantee his clients products with exactly the same size, weight and shape without compromising taste. Calybra allows him the high capacity required with minimal pressure to his dough. In combination with our weight checker Lybra, the baker can monitor and verify his production runs permanently.

Already after several weeks the baker identified some critical points in his production process, enabling him to improve the mixing procedures. As a result he now runs the batches in less time and reduced his spending on ingredients. He’ll have his investment back within two years.

Example 3: You

Our Scandinavian distributor recognised the money saving potential for Calybra immediately. Too many old dividers were mechanically patched up because they were part of bread lines that were otherwise still in good shape. Our divider fits in virtually every production line and it doesn’t cost the client a penny: their oil supplier pays for it.

Everybody wins: the consumer buys tastier bread, the baker spends less on repairs and last but not least the distributor sells a trouble free product at a healthy margin. In this particular case our distributor sold more dividers in one year than he did in the last five.

His clients tell their story in this short film: https://youtu.be/UtyQO2TFLeQ

Calybra Volumetric Dough Divider

Main features

• A typical user will save up to £5000 per year depending on usage. The Calybra does not consume dividing oil, providing you with huge savings over its lifetime.

• Suitable for any type of dough: soft, hard, sticky, gluten-free…

• Stainless steel dividing head and chamber

• Stainless steel hopper, safety system according to standard EN 12042:2014

• Wheels for easy mobility and sufficient ground clearance (facilitates cleaning of floors)

• Larger range of dividing weight

• Simple adjustment of the dividing weight by a hand wheel in easy reach

• Stainless steel covers, belt frame and weight adjustment box

• Electrical socket to connect supplementary machines

• Save energy – automatic switch-off at the end of the dividing cycle

• Touch screen control panel with speed adjustment and piece counter with pre-set counting and auto-stop

• Hydraulic dividing system for highest accuracy with respect for the dough quality

![]()